Weld Process Cracks

Solidification cracking

Cracking that takes place during the weld solidification process is termed either hot cracking or solidification cracking and occurs in all steels which have a high sulphur content - sulphur causes low ductility at elevated temperatures.

The low melting point of phosphorous compounds may also be a problem and may lead to solidification cracking.

In order for a crack to develop the solidifying metal must be subjected to a high tensile stress, this may be present as a result of weld metal contraction combined with high restraint in the transverse direction. A poor joint design, that does not diffuse heat, will also increase the chances of solidification cracking.

Solidification cracks usually occur longitudinally down the centre of a weld because of the segregation of impurities and have a blunt profile compared to other crack types.

Solidification cracks in the final crater, or poor stop start positions, may have a branch like, multifaceted appearance. These crater cracks can often be referred to as star shaped, hence the alternative definition ‘star crack’.

If a high longitudinal stress was present this may cause transverse cracks to develop, e.g. on large submerged arc welds.

Liquation cracking

Solidification cracks in welds may be due in part to the presence of materials within the metal which have a lower defined melting point than that of the metal itself. These low melting point materials usually accumulate at the grain boundaries and can cause problems in the HAZ near the fusion boundary where melting of the parent metal does not occur, but where the temperature is high enough to cause melting of the grain boundary. If this melting occurs in the presence of a high tensile (contraction) stress, then the boundaries will be pulled apart and a liquation crack occurs.

Within the steel itself, sulphur is the major liquation material. If the welding involves a very high heat input, the sulphur in the HAZ is taken into solution by the surrounding steel and precipitates out during cooling as sulphides, causing embrittled grain boundaries which significantly weaken the steel. If such an occurrence has happened, the steel is said to be burned. Copper pick-up may also cause this particular form of liquation cracking.

Liquation cracks are very small and can initiate hydrogen cracking.

Hydrogen induced cracking

The presence of hydrogen causes general embrittlement in steel and during welding may lead directly to cracking of the weld zone, hydrogen induced cold cracking (HICC) being one term that is a form of hydrogen related problems.

Hydrogen enters a weld via the welding arc. The source of hydrogen may be from moisture in the atmosphere, contamination on the weld preparation, or moisture in the electrode flux. With the MMA and SAW processes, the selection of flux type will also affect the H₂ content.

The intense heat of the arc is enough to breakdown the molecular hydrogen (H₂) into its atomic form (H). Hydrogen atoms are the smallest atoms known to man and therefore can easily infiltrate amongst the iron atoms while the weld is still hot. When the weld area is hot, the iron atoms are more mobile thereby producing larger gaps between themselves, i.e. the steel is in an expanded condition.

As the weld cools down, most of the hydrogen diffuses outwards into the parent material and atmosphere, but some of the hydrogen atoms become trapped within the weld zone. This is due to the iron atoms settling as the weld cools, therefore the gaps between them become smaller, i.e. the steel is contracting.

Note: Hydrogen cracking may not occur until; the component has fully cooled (24-48hrs) after welding. (Further information on HICC can be found in PRT5)

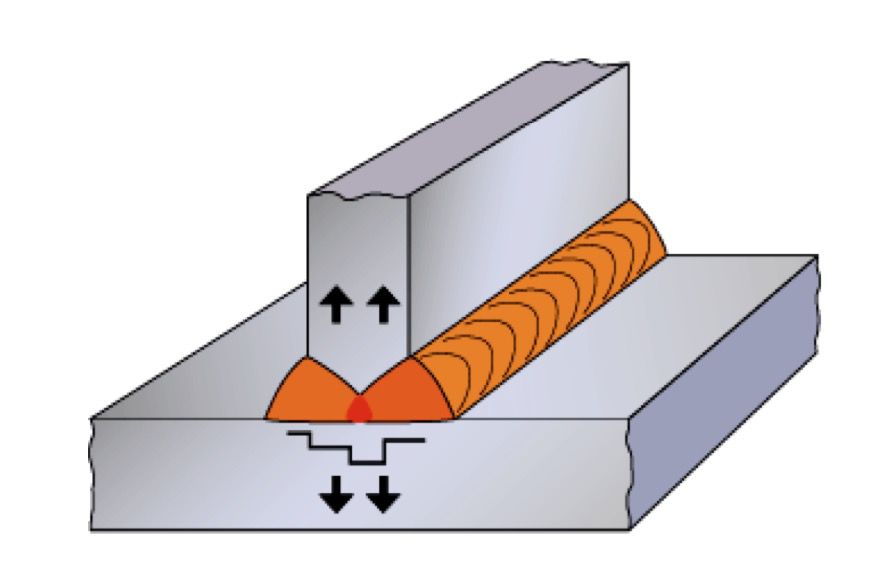

Lamellar Tearing

Lamellar tearing has a characteristic step like appearance. It may occur in the parent plate or HAZ of steels with poor through thickness ductility where the fusion boundary of the weld is parallel with the plate/pipe surface, i.e. lamellar tearing only occurs in the rolled direction of the parent material. It is usually associated with restrained joints that are subjected to through thickness stresses on corners, ‘T, K, Y’ configurations ,tees or fillet welds joining thick plate which have a high sulphur content, although other non-metallic inclusions may also play a part. The presence of hydrogen increases a steel’s susceptibility to lamellar tearing quite significantly.

Lamellar tearing is caused by welding but is a parent metal defect and not a weld material defect.

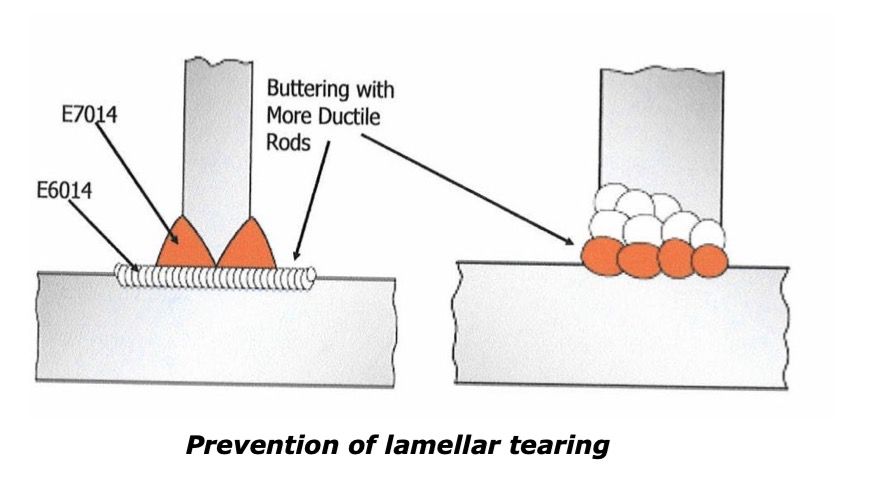

The through thickness ductility of the parent material may be assessed by using the short tensile test - see BS EN 1011-2.

A buttering run is welded onto parent material susceptible to lamellar tearing. This weld metal has higher ductility than the filler metal. Weld contraction which can cause the parent metal to tear now only causes the buttering pass to deform thus preventing lamellar tearing from occurring.

Re-heat cracking

Re-heat cracking - also known as stress relaxation cracking - mainly occurs in the HAZ of welds, particularly in low alloy steels during post weld heat treatment or service at elevated temperatures.

Most alloy steels are subject to an increase of embrittlement of the coarse grained region of the HAZ when heated above 600°C, the problem is worse with thicker steels containing Cr, Cu, Mo, V, Nb and Ti; S and P also have an influence. Typical steels susceptible would be the 2 Cr-Mo-V types, e.g. creep resisting steels.

In the HAZ area, the defect which promotes re-heat cracking could be an existing liquation crack.

During post weld stress relief and at high operating temperatures, the residual stresses will be relieved by creep deformation which involves grain boundary sliding and grain deformation. If, due to high creep strength, these actions cannot occur, the grain boundaries may open up into cracks.

Re-heat cracks most frequently occur in areas of high stress concentration and existing defects. They are not unknown in the weld area where the cracks may originate from sharp profiles, e.g. incomplete root penetration or at the toes of badly shaped fillet welds.

Precautions against re-heat cracking include toe-grinding, elimination of partial penetration welds, the rejection of poor weld profiles, the selection of steels resistant to liquation cracks, the use of the lowest strength weld metal acceptable and controlled post weld heat treatment.

Note: A crack which has only been found after post-weld heat treatment is not necessarily a re-heat crack.